Fire risk management & evacuation | Have you really considered how you would help others?

Fire Risk Management & Evacuation | Have you really Considered How you Would Help Others?

Ecocell® is the only solution for self evacuation in the event of a fire available today. M V Lifts have been installing Ecocell® evacuation lifts for more than 10 years, with over 200 units now installed throughout the UK. Ecocell® self evacuation lifts offer unrivalled quality and performance in this sector

The latest health and safety and fire regulations as quoted in the The Regulatory Reform (Fire Safety) Order 2005 state a ‘responsible person’ for all buildings, commercial or residential ‘must carry out a fire safety risk assessment, implement appropriate fire precaution and protection measures that arise from the risk assessment, and maintain a fire emergency plan’ whilst the Disability Discrimination Act ‘provides for the safe and adequate provision of evacuation procedures for all who are mobility impaired’

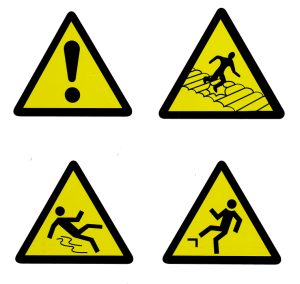

Not having safe evacuation procedures in place can be potentially dangerous not only for you, your staff and third party visitors in any commercial premises but also your family and friends in any residential environment.

Would an evacuation chair be your first choice or last resort?

In the event of a fire, it is considered that lifts should not be used at all. As an independent UK leading lift installer and service & maintenance company, M V Lifts would say that this is generally true for all non-evacuation lifts. However there are instances where people who have a mobility impairment, a disability or who have become injured in the event of the fire that would benefit from having access to the EcoCell® particularly in an evacuation situation.

One common and considered cost effective option is to use evacuation chairs, solely for use in conjunction with staircases. They are often seen as the ‘simplest, most practical solution’ because of the limited knowledge of cost efficient alternative solutions.

Despite being light weight and easy to use devices evacuation chairs rely on the assistance of others for the quick and safe removal of people who are mobility impaired – putting not only the evacuees at risk but also those enabling the evacuation – and often at times of heightened stress and anxiety.

More importantly evacuation chairs only offer one-way transport (downwards), with the enabler only recommended to lift someone of their own body weight or less making the use of an evacuation chair somewhat a ‘lottery’ decision in an emergency situation. This puts not only the evacuee at risk but also those enabling the process. The costs associated with fitting the EcoCell® are highly competitive when you consider

- the scale of personal injury claims brought forward by evacuees and / or enablers using evacuation chairs under duress and which are rising year on year. Repudiation rates have historically been high for public liability claims and the Compensation Recoveries Unit data shows an increase from 44% in 2011 to 50% in 2014.

- Repudiation rates continued to increase into 2015 (53%) according to the report ‘An analysis of the personal injury claims market’ by Weightmans Market Affairs Group 2015

- the EcoCell® is able to function daily as normal lift, helping individuals seeking assistance travelling up and down, whilst offering unique assistance in times of emergency evacuation

- the Ecocell® self evacuation lift can offer significant operating cost reductions and energy savings whilst being relatively easy to install as an upgrade

- the EcoCell® lift also continues to run in the event of total power loss to the building and not only when required for evacuation purposes

The Ecocell®

- can operate for up to 100 journeys on battery backup

- the batteries can be trickle charged from a single phase supply or from eco-friendly photo voltaic panels and/or wind turbine sources

- can be readily converted to fully compliant evacuation lifts

- can contribute towards BREEAM credits under Ene 8 ’energy efficient lifts’

- only requires a 900mm pit depth when retro-fitting older less efficient lifts

Through extensive research, listening to our client feedback, and working with our supply chain M V Lifts have recently developed a number of innovative design changes. These include PV Cells for battery charging, visual battery monitoring and our latest innovation – the integrated access control for ‘self’ evacuation – making it the market leading option for the safe evacuation of mobility impaired individuals in the event of a fire.

With its’ own in-built secondary power supply, which meets the requirement for 20 minutes of standby power (BS 9999), the integrated access control for self evacuation has been designed for use with all standard types of proximity detection systems. This is particularly effective for those systems used by the disabled or those with limited mobility at all times, as well as for evacuation purposes

Moreover, installing the Ecocell® will also allow evacuees to reduce their waiting time in the designated refuge area and occupants could be starting to evacuate the building from the moment that the fire alarm is activated.

The Ecocell® self evacuation lift is fully compliant to BS 9999 and carries a strong BREEAM rating. With its’ unique self evacuation qualities and energy efficiency, the Ecocell® is the only solution for those considering self evacuation at any stage of their project

It’s time to move lifts up your agenda! For more information please see www.mvlifts.co.uk/ecocell, email ecocell@mvlifts.co.uk or call our sales team directly on 0115 973 7550.

Maintaining your machinery

If your machinery isn’t maintained or checked, it may malfunction. If a malfunction occurs, the equipment may go awry, the equipment may overheat and subsequently cause a fire. Along with your machinery, your fire alarm systems and protection should regularly be maintained and checked, so as to ensure it will still adequately function in the case of a fire outbreak. So make sure your fire alarm system is regularly serviced and maintained!

Manufacturing Fire Safety Emergency Procedures

Fire drills where loud machinery and equipment are being operated, are often difficult to carry out. You will need the right alarm system that can be heard over these. However, drills must be carried at least once a year. All full time and temporary members of staff should be aware of the full evacuation process. If your staff are more experienced in fire procedures, the smoother the evacuation process! Additionally, staff need to understand how to use the fire protection equipment available. To get your staff confident with the use of the fire protection equipment, get them fire warden trained!

Therefore, for more information on manufacturing fire safety and the right fire protection, installations and maintenance for your premises. Call our friendly team on 0845 402 3045 or email sales@assured-ltd.co.uk for more information on Fire Protection Service and Maintenance, Fire Alarm Installations, Fire Safety Training or any Fire Risk Assessments!

Published August 2018